The Keg Cycle Part One

Understanding the keg cycle is key to reducing spend on your keg fleet. Each state in the cycle can be minimized through different techniques which will result in a quicker turnaround for each of your kegs meaning a smaller fleet is required to service a given number of sales.

This is part one of a short series so I'll be keeping things general and will expand on a number of topics in later posts.

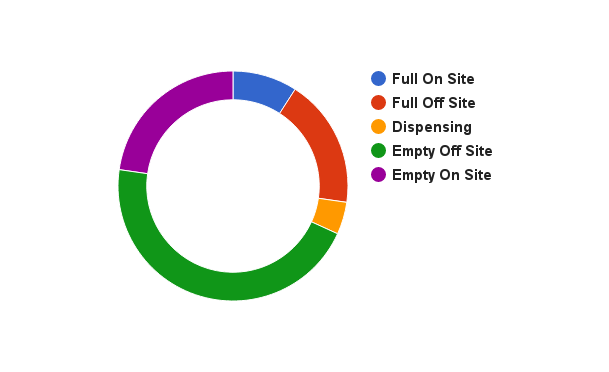

Let's look at the five states of the keg cycle in turn, starting with when a keg is filled.

Filled On-Site

This is your stock on hand. Your production schedule will play a part in how much you keep on hand, e.g. whether you keg-on-demand, keg on only certain days of the week, or keg when you need a tank emptied. Whatever method you use the name of the game is to keep the stock on hand as low as possible (while still meeting demand) so your beer gets to your customers as fresh as possible, and get the keg back as quickly as possible to be refilled.

As well as production (supply-side), demand-side factors can be tweaked to minimize stock on hand. So what can be done there? Being able to preempt sales is key. Wouldn't it be great to know how many kegs your distributor has in stock at the current moment? How many kegs are sitting lined up in a bar's chiller? With BrooDoo Kegs you can see this information in real time. You'll be able to smooth out stock levels by better forecasting short-term demand, and reducing your average keg-cycle time but putting the right product in the keg when it is needed.

Filled Off-Site

Here things feel somewhat out of your hands. The keg has been shipped, you know where and when it has gone, and hope one day you'll see it again. If you know the stock levels off-site, you know which products are backed up and therefore where demand needs stimulating. BrooDoo Kegs allows you to be agile with your marketing, specifically targeting bars/regions and products that you'd like stimulated. With social media this is easier than ever.

Dispensing

Here everyone is happy. Your customers are enjoying your product, the bar is making money, you are making money.

To speed up this part of the cycle involves stimulating demand. The more people that are drinking your beer the quicker the keg is emptied. Simple. In theory. Almost everything you do from product formulation, through production process, to marketing aims to get your beer pouring as quickly as possible. This is obviously out of scope of this article, however knowing what beer is pouring where and when lets you target social media marketing. BrooDoo Kegs allows bars to mark you product as on tap and off tap which lets you know in real time what is pouring where. While bars are not required to scan product on- and off-tap, this can be mutually beneficial for the bar and brewer.

Empty Off-Site

This is the real killer. Empty kegs sitting around but off-site and unable to be filled. Often you have no idea where they are or even whether they are empty or not. If you use a distributor you may not know where and when the keg has gone to a bar. Even when you deliver beer directly to a local bar, you don't know for sure when to collect the empties.

As you know by now BrooDoo Kegs allows you to see where and when your kegs moved after they have left your premises. This helps solve the where. BrooDoo Kegs allows bars to scan kegs as ready for pickup. You can be alerted immediately when a bar scans a keg ready for pickup. This takes care of the when and is mutually beneficial for the bar and brewer. Even if the bar chooses not to use this function, BrooDoo Kegs' reporting allows you to view which kegs have been off-site the longest, or which have gone the longest without a scan so you can proactively chase up your keg fleet.

This state offers the largest gains in reducing the keg cycle time, and with BrooDoo Kegs, is the easiest to target.

Empty On-Site

This is the brewer's buffer. While kegs are sitting around empty they are costing you money. But on the other hand you need a buffer to smooth out any peaks and troughs in supply and demand. Therefore your aim should be to optimize the length of time a keg stays on-site and empty rather than to minimize it. This is done by changing the number of kegs in your fleet. Since you should focus on minimizing the previous four keg states first before looking at altering your fleet size, we will look at this optimization in a following blog post.

So in summing up, the first step to optimizing your keg fleet is reducing your average keg cycle time. You can use various techniques for each state in the cycle, each of which BrooDoo Kegs can help with. Once you have taken steps to reduce your keg cycle time, you can look at ways to reduce your spend on your keg fleet.